EPE Foam (Expanded polyethylene foam)

EPE is polyethylene based foam which is flexible, light weight, resilient and microbe free packaging materials. Above properties along with shake & vibration absorption, scratch proof, low moisture absorption and transmission, chemical resistance and zero abrasion and make the conventional materials like paper shavings, honey comp, rubberized coir and PU foam. (See more material futures)

EPE is polyethylene based foam which is flexible, light weight, resilient and microbe free packaging materials. Above properties along with shake & vibration absorption, scratch proof, low moisture absorption and transmission, chemical resistance and zero abrasion and make the conventional materials like paper shavings, honey comp, rubberized coir and PU foam. (See more material futures)

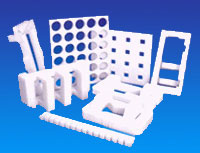

IP fabricate and provide special packing for customized variety of packaging on your product specifications. EPE Foam is available some standard EPE POUCHES, EPE SHEET, EPE FITMENTS and many more. EPE is especially ideal for Automobile, Electronics and Electricals, Handicrafts, leathers and many more.

EPE POUCH is available as per your quality requirements. For example 2D & 3D POUCHES, ENVELOPE POUCHS & TOP COVER POUCHES. It’s available in sheet forms also.

EPE FITMENTs is fabricated and provide as per your product shape and dimensions. It’s is ideal for electronics base and scientific base products. It’s is CFE–FREE and Eco-friendly & pollution free. It’s is the replacement of PS foam and Paper made blocks.

EPE FOAM – Special Features:

- Protection & Resiliency: EPE is closed cells, micro cellular structure and high resiliency is very effective to absorb the shock & vibrations during handling, transit and storage thereby efficiently protect the product from damages.

- Abrasion Resistance: The soft, light, smooth and uniform surface I texture it offers zero abrasion, ensure resistance to abrasion marks and scratches to the product.

- Flexible: The highly flexible characteristic enables twisting around the product for specific wrap around applications. It resumes its normal shape on removal of load factor.

- Moisture Resistance: The low thermal conductivity and near total resistance to moisture absorption makes EPE Foam an excellent insulating and water proofing material far superior to the conventional applications.

- Non Corrosive Non Toxic: EPE Foam is inert to most of the corrosive chemicals like acids and alkalis. It is resistant to fungi and insects and hence can be a food packaging medium.

- Easy fabrication: EPE Foam lends itself to easy fabrication into a variety of shapes & structures.

- Laminated: EPE Foam can be laminated with aluminium foil paper, PP, HM BOPP, Film, Woven Sack etc. For additional strength and protection specific to customer requirements.

- Anti-Static: EPE Foam is naturally anti-static and does not attract dust. Special anti-static grade are also available for packing of electronics, to product them from electric charge in the environment / ambiance.

- Effective temperature range: All these superior properties of EPE Foam remain unaltered in a temperature range of -50oC to +70oC allowing a wide spectrum of possible effective applications.

- Thermal Insulation: EPE Foam being closed cell material, low moisture absorption and most importantly has low thermal conductivity (K-VALUE), offers excellent thermal insulation, to maintain the temperature, and in addition also gives water-proofing characteristics, which is more efficient & consistent in comparison to the other conventional materials.

- CFC-FREE: EPE is a CFC-FREE material as well as reusable / recyclable, which makes it as Eco-Friendly & Pollution Free.

EPE Technical Specifications:

| SL NO | PROPERITY | UNIT | SPECIFICATION |

|---|---|---|---|

| 1 | Density | Kg/m3 | 25 to 45 |

| 2 | Tensile Strength at ambient temp | Kg/m2 | MD 2.5 to 5 TD 1.8 to 3.5 |

| 3 | Elongation | % | MD80 to 100 TD 42 to 70 |

| 4 | Compression Strength at 10% | Kg/m2 | 0.05 to 0.20 |

| 5 | Water absorption after 96 hrs | Volume | 0.01 to 0.50 |

| 6 | Water Vapour Transmission | Gm/m3 | 20 to 25 |

| 7 | Buoyancy (Fresh Water) | Kg/m3 | 915 to 940 |

| 8 | Thermal C conductivity | k/cal/M.Hr.c | 0.020 to 0.028 |

| 9 | Service Temperature | ºc | -50 to +70 |

Top

Top